CNC machining has several types of machining. The most common types are CNC turning and CNC milling. Most people may find it difficult to distinguish between the CNC milled parts, and the CNC turned parts because both types produce highly precise components. But, the truth of the matter is that CNC milling and CNC turning are pretty different. Therefore, this post aims to update you on the difference between CNC milling and CNC turning.

The difference between CNC milling and CNC turning

1. Operation difference

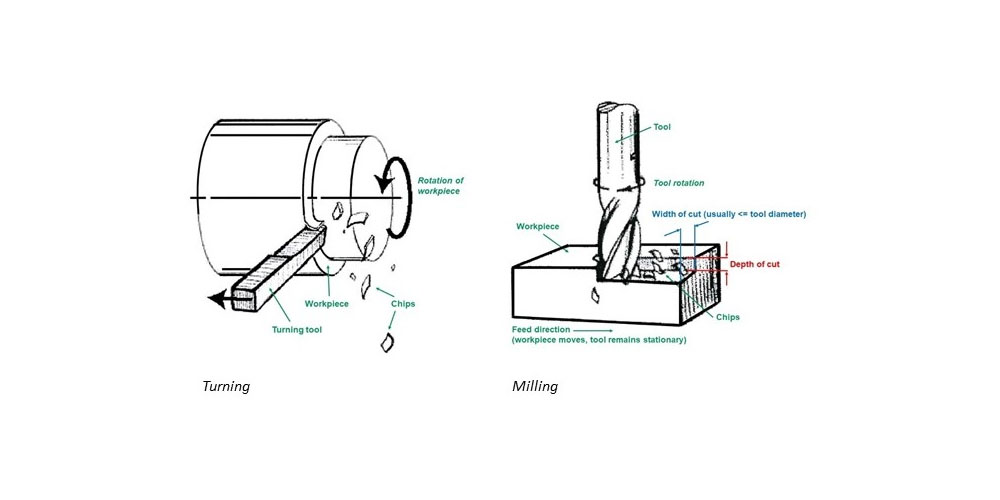

CNC milling operates by spinning the cutting tool on a fixed workpiece. It mainly utilizes the rectangular or square bare stock to manufacture parts. In comparison, the CNC turning machine operates by rotating the workpiece on the cutting tool. It mainly utilizes the round bar stock for producing parts.

2. Functional difference

The CNC milling works best on irregular and flat surfaces, while CNC turning is best used on conical and cylindrical surfaces.

3. Production abilities

CNC milling production abilities involve various processes, like thermal, chemical, mechanical, and electrical. It ensures that the workpiece has high conservation effectiveness, which contributes to decreasing material costs against the CNC milling machine lifespan. Additionally, CNC milling machine manufactures parts, like prototype parts, complex parts, precision parts, and short-term manufacturing parts. On the other hand, CNC turning machines processes involve; parting, boring, knurling, drilling, grooving, and facing.

4. Chips produced

CNC turning produces continuous, fragmented, and discontinuous chips while CNC milling develops discontinuous chips.

5. Versatility

Turning is mainly used in manufacturing bored holes and circular diameters. But CNC milling produces non-circular and non-asymmetric shapes and features, like radial corners, slots, and square pockets. Therefore, CNC turning is less versatile than CNC milling.

6. Machine tooling

There are different tools used in the CNC turning machines and CNC milling machines. But, the most common difference in tooling is that CNC turning has a single-point cutting tool while the CNC milling machine has a multi-point cutting tool.

7. Cutting difference

CNC turning cutting is continuous while the CNC milling is intermittent; CNC milling cutting teeth disengage and engage with the workpiece. In CNC turning, the cutting tool is in constant interaction with the raw material.

Similarities between CNC milling and CNC turning

· Computer-controlled

Both CNC turning and CNC milling are computer-controlled. They use the CAD software to guide them on the required part machining. The computer-controlled processes are automated. Therefore, one operator can monitor several machines thus reducing the labor costs. Furthermore, the computer-controlled procedures guarantee more minor errors.

· Use subtractive production techniques.

Both CNC milling and turning uses subtractive methods, where the material is slowly chipped away from the workpiece or raw material until a final shape is attained. Additionally, they both produce heat, thus using cutting fluid to reduce the impacts of heating.

Conclusion

While researching CNC machining, you will find that CNC milling and CNC turning are commonly used. Therefore, it may be a little challenging to distinguish between the two. Both machining procedures serve the same function of producing high-precise components. But use different processes and tools.